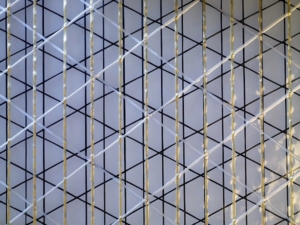

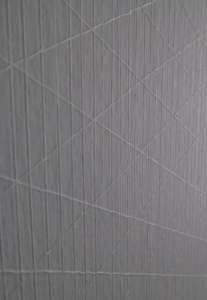

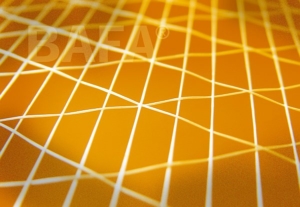

Examples for textures of laid scrims

What are laid scrims?

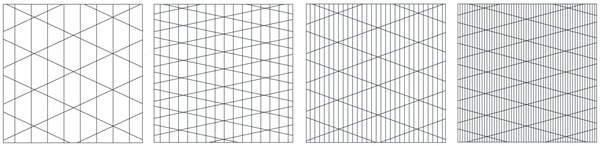

In contrast to close-meshed fabrics BAFA®– thread scrims consist of threads that cross diagonally at a more or less large distance..

They are impregnated with an adhesive “binder” during the production process. Once the binder has dried, the contact points are glued. This allows for any thread spacing and angle.

Depending on the number of longitudinal and diagonal threads, a narrow- or wide-meshed diamond structure is created. For wallpaper, the geometric design is an unusual alternative.

Depending on the binder material, you can decide during configuration which properties your wallpapers should have. Stiff or soft, tear-resistant, waterproof, ecologically degradable, flame-retardant, etc.

Laid scrims. Here: In several layers

Extraordinary textured wallpaper

BAFA®-laid scrims are suitable for use on the surface and underside of wallpapers.

On the surface, thread scrims are a real eye-catcher.

With natural fibres like cotton, jute, hemp or sisal, they make an ecological statement. The wallpaper remains recyclable as waste paper.

Materials such as glass fibre, carbon fibre or steel fibre, on the other hand, emphasise a technical design.

On the underside, thread scrims create a discreet wave look in the wallpaper. Depending on the thickness of the threads, the wave effect can be finely adjusted.

Your supplier for laid scrims on wallpapers

Added value through quality and efficiency

BAFA®-laid scrims give you the opportunity to add value through higher product quality and an exceptional design.

Compared to usual printed or embossed wallpapers, your distribution can justify a more interesting price.

Bottom line: Extra sales, higher margins, more customers and a strengthened brand.

Your supplier for laid scrims on wallpapers

Flexible, stable, lightweight, individually customizable

You can customize your products by configuring variables of BAFA®-laid scrims to meet your demands:

- Materials, combination of materials and their characteristics (e.g. soft, hard, waterproof, wash and dry cleaning resistant, heat-sealable, flame-retardant)

- Thickness of the threads

- Width of the mesh

- Elongation (1,7 – 23%)

- Breaking load (2,2 – 448 N)

- Tenacity (13 – 355 cN/tex)

- Angles (and hence force transmission) of crossing threads

- Colors

- Impregnators (Prepregs)

Suitability for Automated Production Processes

BAFATEX supplies laid scrims in coiled widths – on request just-in-time. With their excellent cuttability and punchability they enable a high build quality and a high processing speed.

With their excellent cuttability and punchability they are perfectly applicable for cutting production lines.

Sustainable, biodegradable reinforcements

BAFATEX is committed to the transformation of industry towards sustainable production. We supply manufacturers with ecologically sustainable laid scrims made of renewable raw materials / natural yarns.

This added value enables you to win new customers, avoid plastic waste and more easily meet the requirements of the packaging laws.

(read more: Examples for the packaging industry)

Know How and Consulting

As a matter of course we are certified by DIN ISO 9001 (since 1994) to assure a uniform and high quality of our products.

Based on our experience of decades and our technical expertise we would be pleased to consult you about the range of characteristics and processing technologies of our scrims.

Technical Literature

Joseph F. Hanlon, Robert J. Kelsey, Hallie Forcinio: Handbook of Package Engineering

Walter Soroka: Fundamentals of Packaging Technology